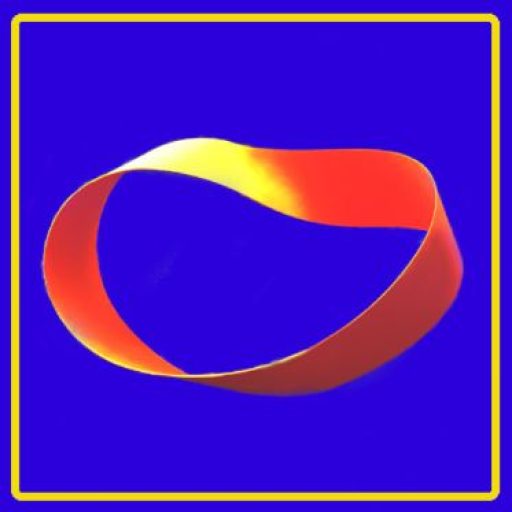

Header image: “Pipe Dream” (2014), by Douglas Walker in foyer of SW9 at BCIT (see bottom of page)

I’ve been fortunate to encounter Brian Ennis in SW9 many times now. He and I have spent many hours discussing our enduring Irishness, as well as all kinds of interesting inroads into teaching and learning. He also offered to school me on the machine lathe and I jumped at the chance.

My notes from this learning are below; they are a sort of continuation of this kind of learning that I started in the UBC Student Machine Shop Course and expanded with the short time I have spent on the wood lathe in SW9.

- Windage

- Morse taper:

High-speed steel; game changer (cf. Bessemer steel)

- Superior to high-carbon steel tools in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high-carbon steel, hence the name high-speed steel.

- Taylor-White process: a series of experiments with heat treating existing high-quality tool steels, heating them to much higher temperatures than were typically considered desirable in the industry

- …their experiments were characterised by a scientific empiricism in that many different combinations were made and tested, with no regard for conventional wisdom or alchemic recipes, and detailed records kept of each batch. The result was a heat treatment process that transformed existing alloys into a new kind of steel that could retain its hardness at higher temperatures, allowing much higher speeds and rate of cutting when machining.

- High-speed steel tools are the most popular for use in woodturning, as the speed of movement of the work past the edge is relatively high for handheld tools, and HSS holds its edge far longer than high-carbon steel tools can

How Differentials Work: Viscous Coupling https://auto.howstuffworks.com/differential5.htm

- a disadvantage of the viscous coupling: No torque transfer will occur until a wheel actually starts slipping.

- A simple experiment with an egg will help explain the behavior of the viscous coupling. If you set an egg on the kitchen table, the shell and the yolk are both stationary. If you suddenly spin the egg, the shell will be moving at a faster speed than the yolk for a second, but the yolk will quickly catch up.

- To prove that the yolk is spinning, once you have the egg spinning, quickly stop it and then let go — the egg will start to spin again (unless it is hard-boiled).

- Missy

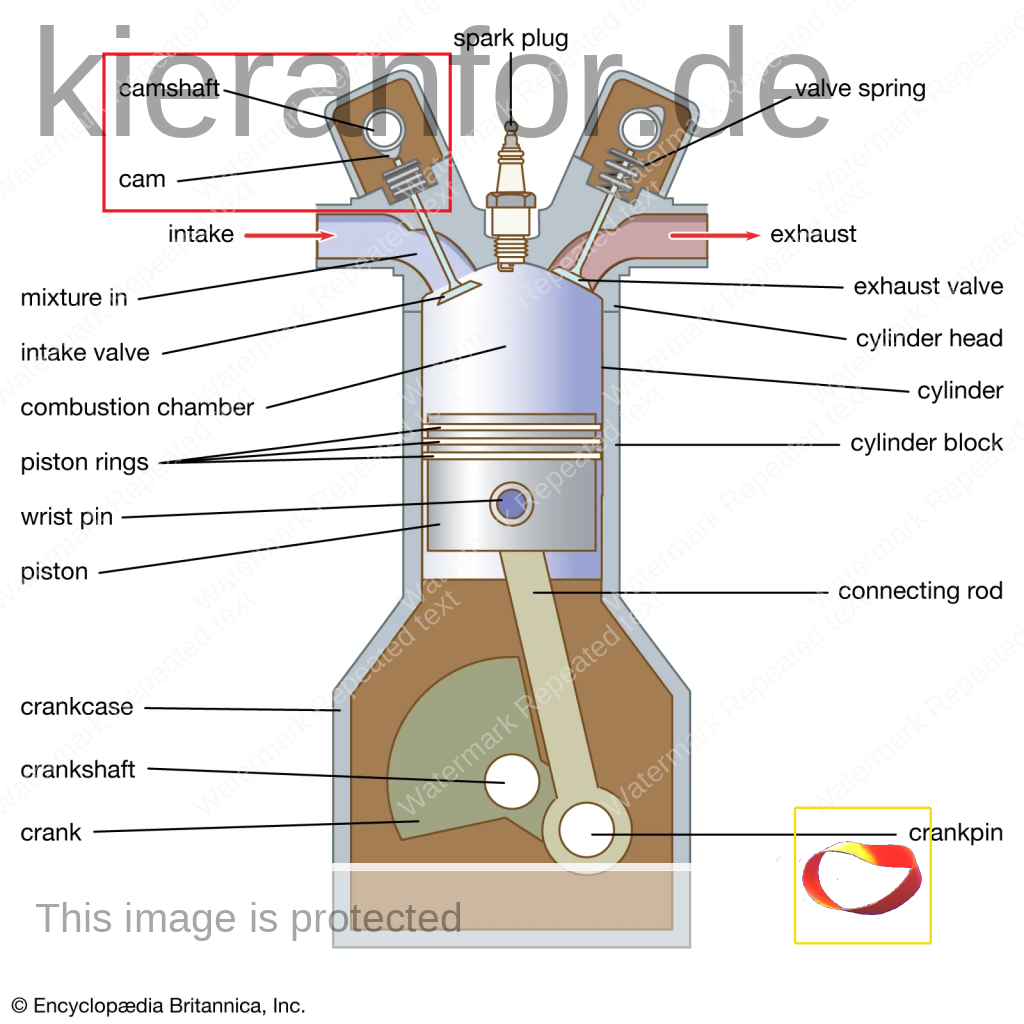

Drill v ream v bore

“If ya want a thing to fit, you need a ream”

The Dub

Drilling is usually the first step in creating the hole, followed by boring which sizes the hole, then reaming which finishes the hole: https://gammons.com/blog/boring

- Centre drill; peck drill;

Oct 18, 2024

- Rory gave me a heads-up that they’d be doing welding for the morning so I showed up ready to learn and burn (/melt / fuse/ …)

Gratitude to Justin Pater for schooling me on MIG welding

KF: remove phone number

Sept 2024

- Gauge blocks:

- (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks

- invented in 1896 by Swedish machinist Carl Edvard Johansson

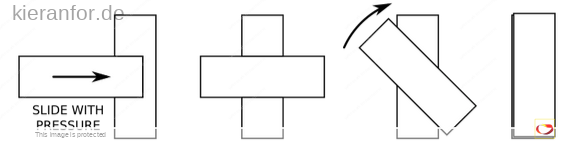

- can be joined together with very little dimensional uncertainty… by a sliding process called wringing

- The ability of a given gauge block to wring is called wringability; it is officially defined as “the ability of two surfaces to adhere tightly to each other in the absence of external means.”

- What a great term. Wondering if I could apply this to describing relationships…

- made of a hardened steel alloy, while calibration grade blocks are often made of tungsten carbide (WC), chromium carbide (CrC) or ceramic (SiO2-based) because they are harder and wear less

- The length of each block is actually slightly shorter than the nominal length stamped on it, because the stamped length includes the length of one wring film, a film of lubricant which separates adjacent block faces in normal use.

- calibrated to be accurate at 20 °C (68 °F)

- the stacked error from even multiple blocks is usually negligible in all but the most demanding uses

- Ford ‘go’ and ‘no-go’ gauges ⬇

- “Scribe margin”

- cabinet-making – made too small; scribe margin = “area of forgiveness” to accommodate wonky wall. Measured “just right” means there’s no wiggle room